Graphite products for high temperature industrial furnaces

graphite plates

- Phone: 86-17660618685

- Tel: 86-053287431226

- Email: holden.bfgraphite@aliyun.com

- FEEDBACK

Graphite Products for High temperature Industrial Furnaces

Introduction:

There are many kinds of industry furnaces in modern industry. For example resistance furnace, induction furnace, sintering furnace, hot pressing sintering furnace, soldering furnace etc. Such industrial furnace has complex structure, special-shaped & various parts, but high working temperature, many metal, ceramic and other products are difficult to work in the furnaces.

graphite material becomes the optimal choice, because its high purity, being easy to machine into complicated shapes, increasing strength with temperature rising.

Advantages:

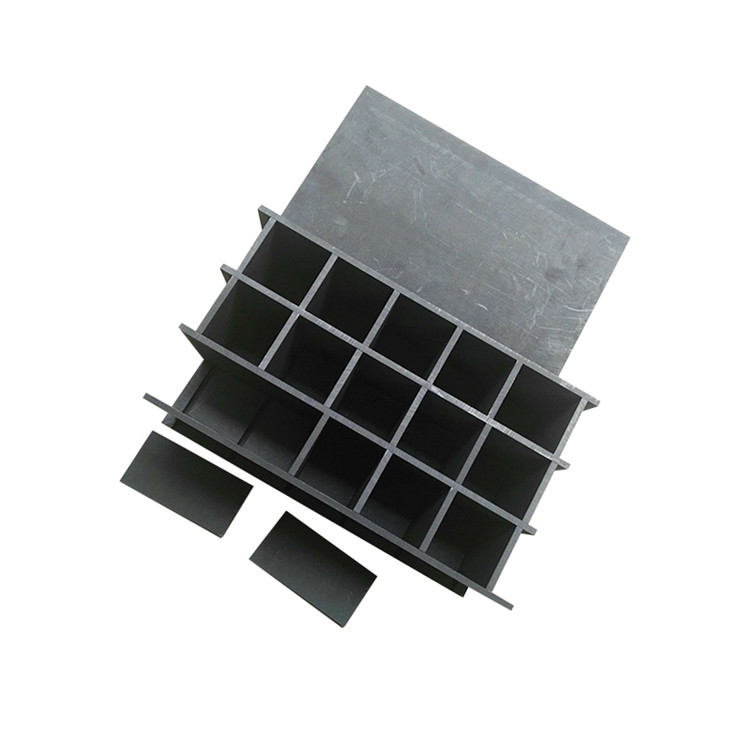

●Graphite kinds: Graphite heating elements、Graphite Thermal Insulation Parts(like graphite thermal shield, graphite insulation board, graphite lining etc)、customized graphite structure parts、Graphite Racks and Graphite Jigs(graphite racks, graphite supports, graphite sintering plates, graphite pushing plates, etc.)、crucibles、customized molds etc.

●Graphite Material. isostatic, molded, vibrated graphite materials can be used for machining graphite products for industry furnaces. Baofeng Graphite choose proper graphite grade, considering comprehensive factors of voltage, working temperature, furnace internal atmosphere and graphite specific resistivity, strength, anti-oxidation performance and material cost.

●Products Machining. In general, most graphite products for industry furnaces need to be closely matched well with furnaces, so the size requirements are very strict, Baofeng graphite can ensure the size tolerance meets the requirements, due to our advanced CNC machining equipment and strong technical skills.

CATEGORIES

- Graphite products for high temperature industrial furnaces

- Graphite Products for Powder Metallurgy

- Graphite products for Electric industry

- Graphite Dies for copper & copper alloys

- Graphite products for Aluminum industry

- Graphite productsfor laboratory/Measuring &Analysis Industry

- Graphite Products for Anticorrosion Industry

- Graphite Products for Foundry

- Graphite Products for Precious Metal Industry

- Graphite products for Mechanics/ Glass/ Electrolysis

- Hot-sale graphite products in stock

LATEST NEWS

CONTACT US

QQ:

Phone: 86-053287431226

Tel: 86-053287431226

Email:

Add: No.8-1, Jinzhou Road, Shui Ji district, Lai Xi city, Qingdao City, Shandong 266000, China.